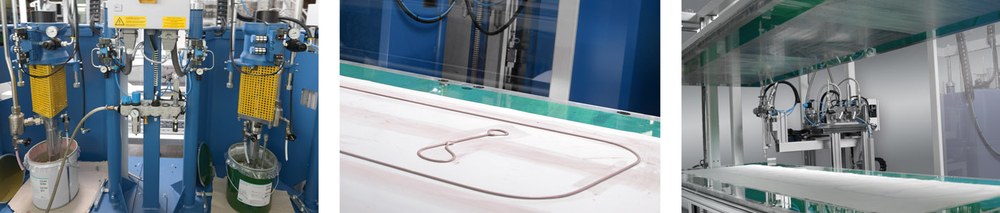

KL 170

CNC-controlled sewing unit for silicone applications onto airbag fabric

Features

- Versions:

- KL 170 (single set-up): for prototyping

- KL 170 (double set-up): for series production with overlapped working method - Positioning of the cuts with loading aids in the table as well as fixation with vacuum suction unit in the table and the lid

- Reproducible constant height of the silicone application is guaranteed by servo-motorically movable distance height adjustment

- Operation field in sizes from 600 x 600 mm up to 3,500 x 800 mm

- Liftable and movable silicone applicator for direct path programming

- Free-programmable measurable dosage unit for even silicone application, suitable for 2-component silicones

- Vacuum system for exact positioning of both material layers

- Height of the silicone application with servo-motorically movable distance height adjustment

- Automatic monitoring of airbag material loading

- Reproducibility of the silicone application with gear pump

- Easy re-tooling of the vacuum station for other airbag models

Options

- Upon customer request

kl170